Pipetting is one of the most fundamental tasks in molecular biology laboratories, yet it is also one of the most critical sources of variability, inefficiency, and error. As laboratories scale up genotyping, PCR, and screening workflows, the choice between manual pipetting and automated pipetting becomes increasingly important. Selecting the right approach can have a significant impact on throughput, data quality, reagent costs, and overall productivity.

In this blog, we explore the advantages and limitations of both approaches and explain how automated pipetting, combined with 3CR Bioscience’s PACE® genotyping chemistry and GeneArrayer liquid handling platforms, can transform modern PCR and genotyping workflows.

Manual Pipetting: Flexibility with Limitations

Manual pipetting remains common in many low-throughput or early-stage laboratories. It offers flexibility, low upfront cost, and is well suited for assay development, small experiments, or validation work.

However, manual pipetting has inherent drawbacks when workflows expand:

- Human variability can affect precision and reproducibility

- Limited throughput restricts scalability

- Operator fatigue increases repetitive strain injuries and error risk over long runs

- Higher reagent consumption due to less precise low-volume dispensing

While manual pipetting may be adequate for smaller workflows, it becomes a bottleneck in PCR genotyping, SNP screening, and large-scale studies where consistency and speed are essential.

Automated Pipetting: Designed for Throughput, Accuracy, and Consistency

Automated pipetting systems address these limitations by standardising liquid handling across every sample and every run. For labs processing hundreds to thousands of samples, automation is no longer a luxury—it is a necessity.

Automated pipetting delivers several key advantages:

- Increased throughput: Thousands of reactions prepared per day

- Improved reproducibility: Standardised liquid handling eliminates operator variability

- Reduced reagent usage: Accurate low-volume dispensing lowers per-sample costs with miniaturisation.

- Lower error rates: Automation minimises pipetting mistakes and cross-contamination

- Scalability: Easily adapts from pilot studies to large-scale projects

For PCR genotyping and SNP analysis, these benefits are magnified when automated pipetting is paired with robust chemistry such as PACE® genotyping reagents.

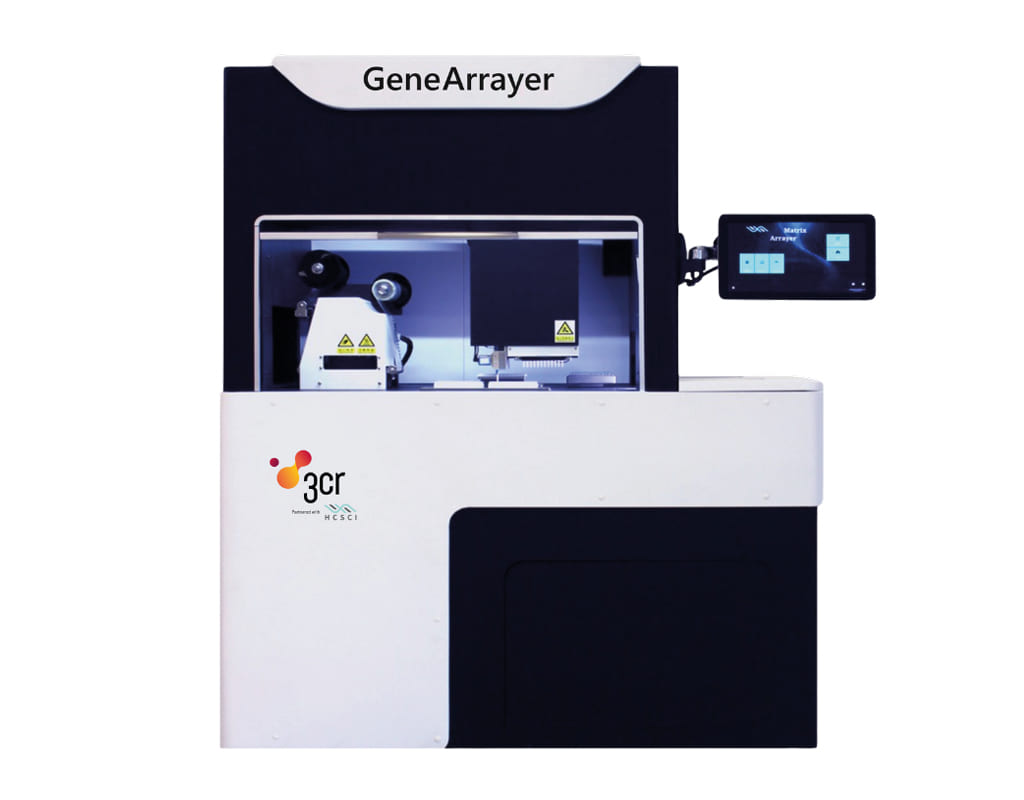

The GeneArrayer Platform: Automated Pipetting Built for Genotyping

3CR Bioscience’s GeneArrayer and GeneArrayer Pro liquid handling workstations are purpose-built to streamline automated PCR setup and genotyping workflows.

The GeneArrayer integrates multiple liquid handling steps into a single automated workstation, including:

- Sample replication

- Assay dispensing

- Pipette washing

- Plate sealing

With precise nanolitre-level dispensing, the GeneArrayer can reduce PCR reaction volumes to below 2 µL and dispense into a 384-well plate in as little as three minutes. This level of precision dramatically reduces reagent and plastic consumption while improving data quality.

Key GeneArrayer Capabilities

- Throughput: Up to 4,600 datapoints per hour

- Plate formats: 96-well and 384-well PCR plates

- Dispensing accuracy: CV < 3–5% across volume ranges

- Integrated barcode scanning for sample tracking and traceability

- Automated plate sealing in under five seconds

A uniquely designed ultrasonic nozzle cleaning system enables effective tip washing, reducing disposable plastic use and lowering consumable costs—an important sustainability advantage.

GeneArrayer Pro: Taking Automated Pipetting Even Further

For laboratories requiring continuous, ultra-high-throughput automation, the GeneArrayer Pro adds an additional robotic arm for automated plate movement. This enables uninterrupted workflows with minimal manual intervention.

By fully automating liquid transfers, reaction setup, and plate handling, the GeneArrayer Pro:

- Maximises laboratory productivity

- Improves reproducibility across large datasets

- Reduces labour and operational costs

- Enables true end-to-end automation

This makes it an ideal solution for breeding programmes, population-scale genotyping, and industrial screening environments.

Why Automated Pipetting Works Best with PACE® Genotyping Chemistry

Automated pipetting is most effective when paired with chemistry designed to perform reliably at low volumes and high throughput. PACE® Genotyping Master Mixes are platform-agnostic and optimised for precision PCR genotyping across all levels of automation.

PACE chemistry delivers:

- Consistent performance across reaction volumes

- Compatibility with all PCR platforms

- ROX normalisation dye options (Standard, High, Low, or No ROX)

- Robust results even in high-throughput, automated environments

When combined with automated pipetting on the GeneArrayer platform, PACE enables accurate, scalable, and cost-effective genotyping workflows.

Choosing the Right Workflow for Your Lab

Every lab has unique throughput and automation requirements. 3CR Bioscience offers modular solutions that scale with your needs:

- Low throughput: Manual pipetting with standard thermal cyclers and GeneScanner fluorescence detection

- Medium throughput: Automated extraction paired with manual liquid handling

- High throughput: Automated extraction and liquid handling using the GeneArrayer

- Ultra-high throughput: Full automation with GeneArrayer Pro, GeneCycler, and GeneScanner

This flexibility allows laboratories to adopt automated pipetting at their own pace while future-proofing workflows for growth.

Automated Pipetting: A Strategic Investment in Lab Performance

While manual pipetting still has its place, automated pipetting offers clear advantages for modern PCR and genotyping laboratories. Improved accuracy, higher throughput, reduced costs, and enhanced reproducibility make automation a strategic investment rather than a simple equipment upgrade.

By combining GeneArrayer liquid handling automation with PACE® genotyping reagents, 3CR Bioscience delivers integrated solutions that empower laboratories to work faster, smarter, and more efficiently—today and at scale.